Outline of NF Board®

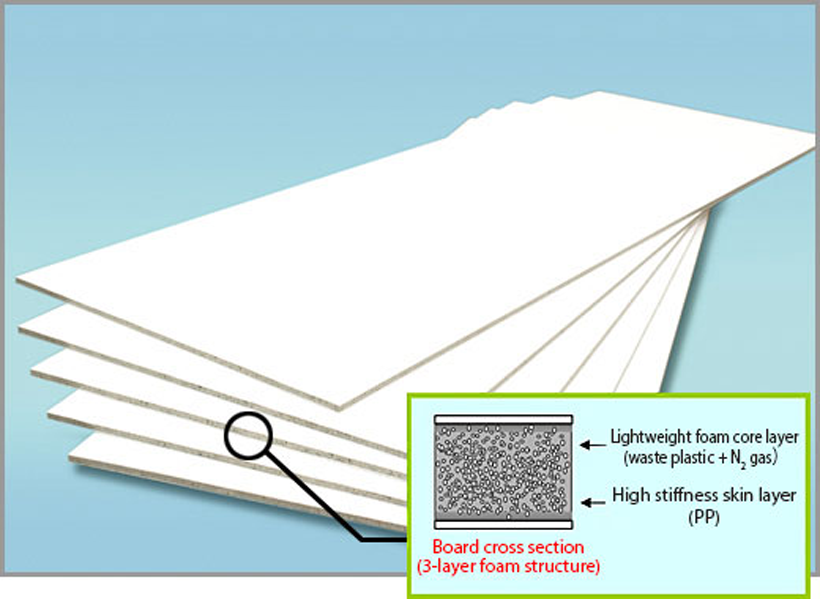

What is NF Board®

- Recycled plastic board made from used plastics discharged by households.

- We promote resource recycling by effectively utilizing used plastic as a substitute for virgin plastic.

- Used NF Board® products are also collected after use and recycled again.

NF Board®production equipment

Economy

- Excellent durability; greatly reduces total cost.

- High abrasion resistance, virtually no surface deterioration.

Free workability

- Same workability as virgin plastic boards is possible.

- Can be cut, drilled and nailed like wood materials.

Easy handling

- Same easy handling as virgin plastic boards.

- Almost zero water absorption; no weight change due to rain, etc.

- Dirt can be wiped off easily.

- Excellent performance as embedded forms.

Excellent performance

- High water/chemical resistance; virtually corrosion free.

- High soundproof/heat insulation performance; suitable for walls.

Secondary recycling possible

Collected used boards can be recycled again.

(Collection is limited to club association members)

(Collection is limited to club association members)

Comparison of Properties

| Item | Thickness(㎜) | Sound transmission loss Frequency 125Hz | Thermal conductivity Room temperature 20℃ |

|---|---|---|---|

| NF Board® | 12 | 21dB | 0.27w/(m・k) |

| Gypsum board | 12.5 | 17dB | 0.22w/(m・k) |

- Same soundproof and heat insulation performance as gypsum board.

Comparison of Features of Plastic Boards

| Item | Material | Outside dimensions | Coefficient of linear expansion (/℃) |

Bending Young’s modulus (kN/mm2) |

Allowable bending unit stress (kN/mm2) |

||

|---|---|---|---|---|---|---|---|

| Width(mm) | Length(mm) | Thickness (mm) | |||||

| NF Board® | Recycled plastic+PP | 600 | 1,800 | 12 | 1.1×10-4 | 1.8 of more | 27.0 or more |

| Plastic board A (other company) |

PP | 600 | 1,800~2,400 | 60, 72 | 7×10-5 | 2.6 or more | 35.0 or more |

| Plastic board B (other company) |

ABS | 300, 600, 900 | 800 | 10,12,15 | 7~9×10-5 | 1.47 | 37 |

| Plastic board C (other company) |

PP+glass fiber | 600 | 600~2,100 | 60, 72 | 2.2×10-6 | 3 | 50 |

Basic Performance of NF Board®

| Item | Performance | Test method | ||

|---|---|---|---|---|

| Workability | Cutting, drilling, nailing | Same as plastic board. | Internal test method (cutting with saw, drilling with drill, nailing with round and screw nails) |

|

| Nail holding force(N/mm) | Round nail | 6~13 | JIS Z2101 "Nail pulling resistance test method" |

|

| Screw nail | 9~22 | |||

| Durability | Scratch resistance (abrasion resistance) | Good | DIN 30678"Painting - General tests" | |

| Impact resistance | Drop weight impact resistance (3kg・5mh) |

No cracks |

DIN 30678 "Drop weight impact test" |

|

| Dropping impact(4mh) | Corner damage (crushing) is slight. |

Internal test method (Drop test from height of 4m) |

||

| Fire resistance | Welding fireball drop | Burns, but fire does not spread. |

Internal test method (Drop test of gas welding fireball) |

|

| Water resistance | Water repellency | Good |

Internal test method (Repellency test during water dripping) |

|

| Swelling caused by water | None | Internal test method (Dimensional change after immersion in water for 1 week) |

||

| Alkaline resistance | No change |

Japan Agricultural Standards "Standard for concrete form use (2/27/2003)" |

||

Specification of NF Board®

| No. | NF(3Layer) | Thickness(mm) | Size | Width(mm) | Length(mm) | Applications | Certified labels |

|---|---|---|---|---|---|---|---|

| ① | NF12 | 12 | 2×6 | 600 | 1,800 |

|

|

| ② | NF5.5 | 5.5 | 2×6 | 600 | 1,800 |

|

|

| No. | SL(Single Layer) | Thickness(mm) | Size | Width(mm) | Length(mm) | Applications | Certified labels |

| ③ | SL3 | 3 | 14 | 1,420 | 1,420 |

|

|

- All types of NF Board® listed above have the certified label of Eco Mark.

- Due to the properties of the product, color may change (white to cream) in some cases.

- When ordering, please confirm dimensional difference and inventory status.

- In some regions, products are sold under the name of AD Board White.