Basic Policy

Action Guidelines

- JFE Plastic Resource Corporation observes all applicable related laws and regulations.

- The Company implements, maintains and continuously improves an Environmental Management System.

- Concretely, the Company makes the following efforts:

- (1) Reduction of CO2 emissions by promoting energy saving and recycling of plastics.

- (2) Resource saving by reduction of industrial water consumption, etc.

- (3) Reduction of industrial wastes by improvement of the recycling rate, etc.

- (4) Active efforts in connection with regional environmental education by receiving visitors for plant tours, participation in environmental exhibitions, etc.

- (5) Promotion of Green Purchasing.

JFE Plastic Resource Corporation

President and Representative Director, Nozomu Tamura

Quality and Environmental Policy

Basic Philosophy

JFE Plastic Resource Corporation (hereinafter, the Company) contributes to realizing reductions of environmental loads and the formation of a recycling society through its plastic recycling business. The Company conducts business activities that maintain the priority of enhancing customer satisfaction by clarifying, understanding and consistently satisfying customer requirements and applicable legal and regulatory requirements, and determining the opportunities and risks that can influence its capability to improve customer satisfaction and the conformance of products and services. All employees act in concert to conduct quality and environmental management in accordance with the Quality Management System and Environmental Management System.

Basic Policy

- In conducting its business, the Company establishes and observes Quality and Environmental Manuals in accordance with the Quality and Environmental Management Systems for the purposes of conducting business activities based on the two axes of enhancement of customer satisfaction and reduction of environmental loads, and achieving the growth of its business and reduction of social costs by recycling.

- The Quality and Environmental Management Systems apply to all organizations and all activities, products and services of the Company.

- As a constituent member of industrial complexes, eco-towns and next-generation energy parks, the Company prevents environmental pollution and maintains, improves and continues to reduce environmental loads caused by its business activities and environmental loads arising due to business.

- The Company observes related laws and ordinances and other requirements.

- The Company promotes continuous improvement of the Quality Management System and continuous improvement of the Environmental Management System for improvement of environmental performance.

JFE Plastic Resource Corporation

President and Representative Director, Nozomu Tamura

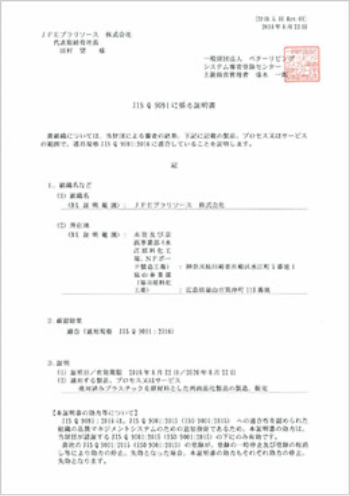

JIS Q 9091: 2016 “Self-Declared Statement of Compliance”

Declaration of Compliance

5-1 Mizue-cho, Kawasaki-ku, Kawasaki, Kanagawa Prefecture Fukuyama Division

Fukuyama Division

113 Minooki-cho, Fukuyama, Hiroshima Prefecture

JIS Q 9091:2016

Quality management system – Recycled plastic materials –

Guidelines for the performance of business processes

Established October 20, 2016

- Quality verification

- Quality verification is conducted for recycled products which are to be shipped.

- Quality control standards are established, quality control is conducted, and only items which pass the standards are considered products.

- The transition of product quality is monitored.

- Stability of quality

- Samples of products are stored based on quality control standards.。

- The operating condition of equipment is properly monitored.

- Inspections and maintenance of equipment are properly conducted.

- The content (foreign matter, soiling, etc.) of bales from storage facilities with successful bids is grasped, and efforts are made to stabilize the quality of the recycled plastic recycled materials (recycled products).

- Mixing of nonstandard products is prevented.

- Storage management

- Raw materials and products are stored properly based on storage management standards.

- Action is taken to prevent scattering and wetting of raw materials.

- The inventory and storage conditions of raw materials and products are controlled.

- Traceability management

- The receiving data, municipality and quantity of raw materials are recorded.

- The material balance in production is controlled.

- Management of prohibited substances

- In case products are to be sold to a designated customer, the requirements provided in the delivery specification, etc. exchanged between the two parties are observed.

- Stable supply

- Efforts are made to maintain a stable supply.

- Frequency of measuring instrument calibration

- Control standards are established and internal measuring instruments are controlled, including calibration thereof.

- Unit carbon dioxide emissions in production of recycled products

- The amount of carbon dioxide emissions in recycling is controlled.

- Unit water consumption in production of recycled products

- The amount of water used in recycling is controlled.

- Compliance

- The Company observes the “Plastic Container and Packaging Recycling Treatment Guidelines” established by the Japan Containers and Packaging Recycling Association.

- The Company obtains approvals required by laws and ordinances, and observes the applicable laws and ordinances.

- The Company implements an information security management system.

- Insurance

- The Company maintains fire insurance, etc. for buildings, equipment, and other assets.

- The Company maintains liability insurance for employees.

Organization of Quality and Environmental Management System

ISO Certification / JIS Compliance

ISO14001・9001

JFE Plastic Resource Corporation has received certification under the international standards ISO 9001 : 2015 Quality Management Systems (QMS) and ISO 14001 : 2015 Environmental Management Systems (EMS).

Manufacture and sale of recycled products using recycled product (plastic) as raw material

Address:5-1 Mizue-cho, Kawasaki-ku, Kawasaki, Kanagawa Prefecture

Fukuyama Division (Fukuyama Recycling Plant)

Address:113 Minooki-cho, Fukuyama, Hiroshima Prefecture

ISO14001・9001

JFE Plastic Resource Corporation received certification of JIS Q 9091 : 2016 compliance in August 2018.

Self-declared Environmental Claims Type II Environmental Labeling

In order to proactively disclose information on environment- conscious products to customers, the Company began an environmental labeling certification system in October 2015. This is a self-declared environmental labeling system conforming to ISO 14021.

The environmental label "NF Eco Label" is displayed on environment- conscious products, and information on those products is provided via the internet, etc.

❶ Outline

ISO 14021 : 1999 (JIS Q 14021 : 2000) "Environmental Labels and Declarations/Self-declared Environmental Claims (Type II)" is not a system under which certification is obtained from a third party. Rather, in this Company's business activities, we declare claims for products that meet or exceed voluntary evaluation standards from among those which are evaluated as having beneficial environmental effects. As the method of declaring these claims, the Company displays an explanatory text or environmental label logo mark (the above-mentioned "NF Eco Label").

Note) ISO: International Organization for Standardization, JIS: Japanese Industrial Standards.

❷ Purpose of System

"Promotion of plastic recycling" and "Reduction of environmental loads" in business of recycling used plastic containers and packaging (hereinafter, waste plastic).

❸ Evaluation Standard

Results are evaluated and certified based on the actual results of the previous fiscal year.

Evaluation standards and control values

| Evaluation standard item | Object of evaluation | Standard value | Displayed material | |

|---|---|---|---|---|

| 1 | Reduction of electric power consumption | Plant | Achievement rate of 70% or more against standard value | Eco Action 21 control table |

| 2 | Reduction of fossil fuel consumption | |||

| 3 | Reduction of water consumption | |||

| 4 | Improved recycling rate | |||

| 5 | Reuse of plastic scrap generated in manufacturing process | Amount of charged material / Amount of crushing treatment = 70% or more | Results control form (Oogishima) / Yield confirmation table | |

| 6 | Amount of container and packaging plastic used in products | Product | 7Use of 70% or more | Use process results control form (NF Board® Plant) |

| 7 | Control of acceptance rate | 70% or more | Monthly operation report (Board operation) | |

| 8 | Various certifications as environment-conscious products | Product | Has received certification. | Certificates |

| 9 | System for recovering used products | System | Has actual results of recovery. | Actual results of recovery of used boards |

| 10 | Recycling of OG (off grade) products and mill end materials | Plant | Annual sales amount/Annual amount generated = Actual results of sale of 80% or more | Monthly operation report (Oogishima Monthly Report of Crushing Work) |